- Robotic systems at Amazon operate at a pace of 224 units per hour, slightly trailing behind human workers, who average 243 units per hour.

- While robots maintain a consistent performance, humans can outperform them in speed under certain conditions.

- Ongoing research is vital to enhancing product handling techniques and minimizing damage rates.

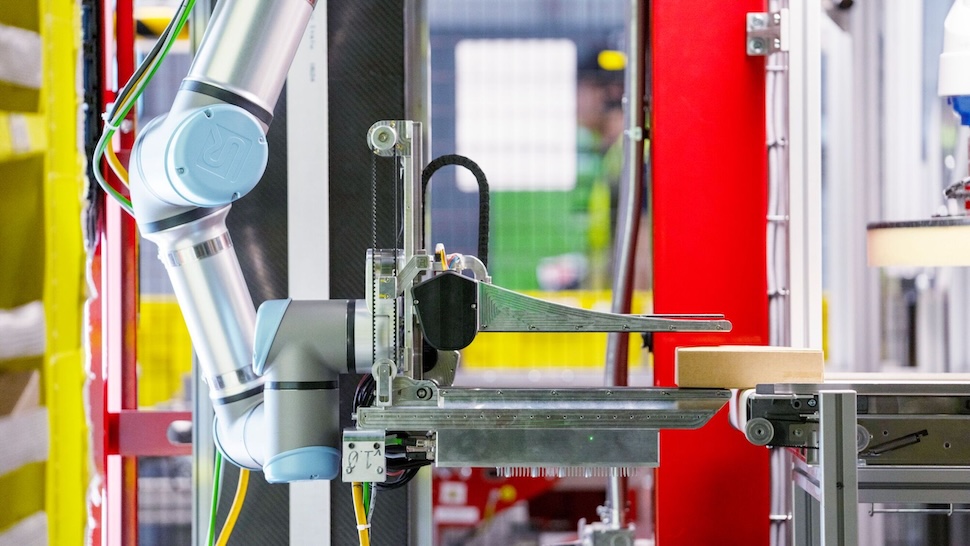

With the introduction of innovative technology such as the recently launched Vulcan robot, which features a sense of touch, Amazon continues to push forward with its development of robots known as ‘Stow’ and ‘Pick’. These machines are designed to streamline stowing and picking operations in their fulfillment centers.

Though significant advancements have been made, Amazon acknowledges that its current robotic solutions are not yet fully capable of replacing human workers, despite yielding promising results thus far.

In performance evaluations, it was found that human employees achieve an impressive average of 243 units processed per hour, compared to robots’ 224 units. While this difference appears minor, it underscores subtle, yet crucial, distinctions in efficiency.

Amazon’s Robots Excel but Still Lag Behind Human Performance

One notable strength of these robotic systems is their consistency. Amazon has stated, “humans often show considerable variability in stowing speeds; they can quickly stow multiple small items, but face difficulties with larger products or in challenging positions, such as reaching for low bins or using ladders for upper shelf access.” Amazon further detailed.

The company also highlighted that humans can effectively multitask with both hands—such as retrieving a bin with one hand while stowing an item with the other—something the current generation of robots struggles to replicate.

However, the performance gap is narrowing, as Amazon’s robots reached an impressive success rate of over 85% in stowing tasks, demonstrating comparable results to human workers across extensive testing conducted in over half a million scenarios.

Nonetheless, integrating robotics into Amazon’s warehouses introduces several challenges, particularly concerning the potential for product damage during operations—be it from drops, improper stowing, or crushing lightweight packages.

As a result, while a complete replacement of human labor appears improbable in the immediate future, hybrid systems that leverage both human and robotic efforts are proving to be highly effective. Continuous advancements in product handling and strategies for mitigating damage are essential moving forward.

“A deeper investigation into the dynamics of complex item interactions could be critical for expanding the capabilities of robotic handling,” noted Amazon’s research team.